Warming Systems with Column Radiators

The two fundamental techniques by which heat-producing units move warmth to their environmental elements are radiation and convection. Radiation is the transmission of nuclear power through electromagnetic beams. All in all, an item is warmed by heat waves transmitting for a hot surface.

The yield of warmth transmitting units is communicated as far as Btu each hour, ordinarily in square feet of comparable direct radiation. The necessary radiation of an establishment is resolved based on the Btu-per-hour limit of each warmth emanating unit.

The kind of warmth emanating unit will rely upon a couple of things. The sort of warming framework, the expense, the necessary limit and the application. Each kind of warmth discharging unit will enjoy comparative benefits and drawbacks that you should consider prior to picking the sort generally appropriate for your new HVAC establishment.

The most widely recognized kinds of warmth emanating units in warming frameworks are radiators, convectors, baseboard radiators, recessed warmers and unit warmers.

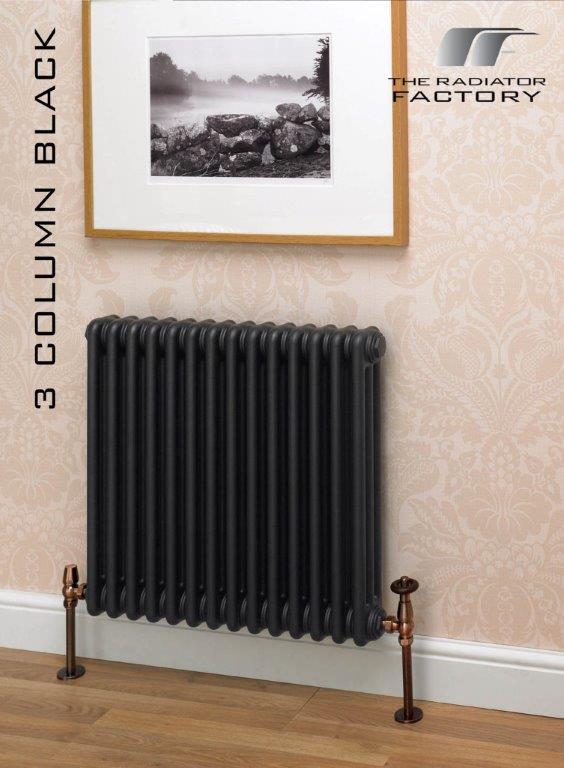

Radiators

column radiators are warmth transmitting unit that communicates a segment of its warmth by radiation and the rest of convection. An uncovered radiator (unsupported) sends roughly 50% of its warmth by radiation, the specific sum contingent upon the size and number of the segments. The equilibrium of the discharge is by conduction to the air in touch with the warming surface and the subsequent dissemination of the air warms by convection.

Cast-iron radiators have been fabricated in both column and cylindrical sorts. Column and huge cylinder radiators have been stopped. The little cylinder radiator with separating of 1 3/4 inches for every segment is currently the overarching type. Rating for different cast-iron radiators is given by the American Society of Heating, Refrigerating and Air-Conditioning Engineers.

The radiators utilized in present day steam and high temp water warming frameworks are planned with areolas situated in both the upper and lower bits of every radiator section; however this was not generally the situation. The most punctual cast iron steam radiators utilized the bygone one-pipe steam warming framework were created with areolas found uniquely in the base area. This was done on the grounds that steam is light and rises rapidly in the radiator pushing air in front of it. The air is then removed through an air vent situated close to the highest point of the radiator; the steam gets back to the lower part of a similar radiator area and afterward travels through the areola to the abutting segment. High temp water cast-iron radiators require areolas at the two closures to further develop water course. Boiling water is heavier than steam and would not move as fast without the help of two arrangements of areolas.